The Top 5 Operational Technology Security Challenges in 2024

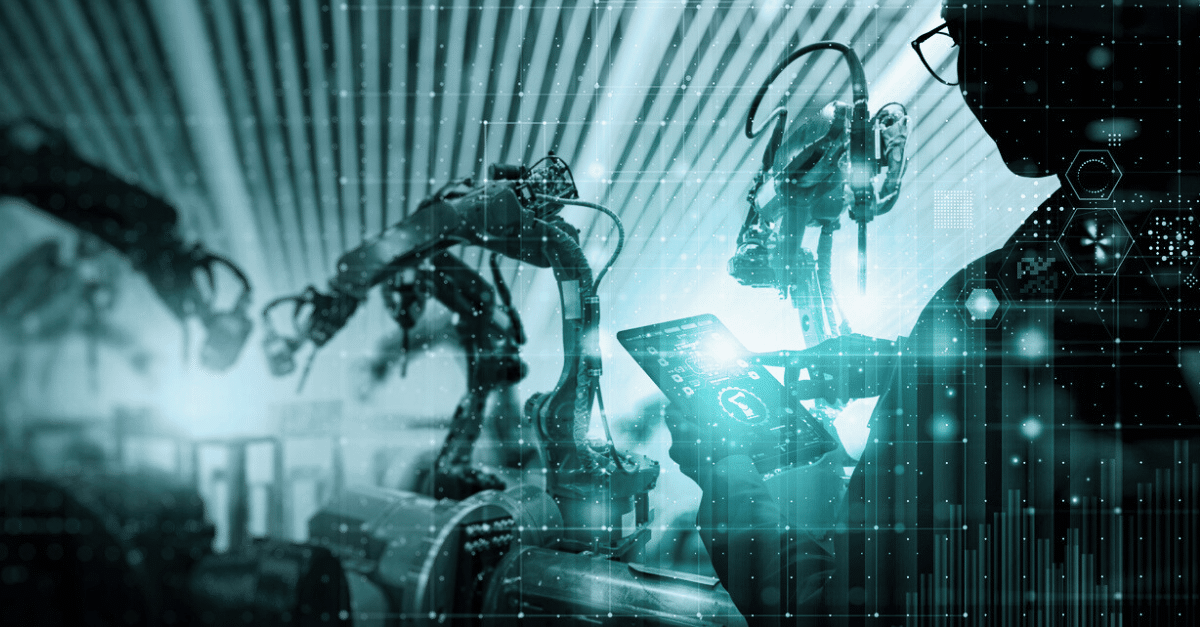

At one time, manufacturing and industrial organizations were “offline,” relying on standalone machinery and isolated control systems. The digital transformation changed everything, including operational technology (OT). Now, connected machinery enables unparalleled levels of innovation with advanced automation, data analytics, and Internet of Things (IoT)-driven systems, enabling faster decision-making and optimized production processes.

Unfortunately, transitioning from offline to connected OT environments has introduced security risks. Cyber attacks against OT systems and other critical infrastructure can have ripple effects far beyond the factory floor, potentially impacting entire supply chains. In this evolving threat landscape, understanding how to secure OT environments is critical to ensuring business continuity and protecting manufacturing and industrial organizations from cascading impacts.

5 Cyber Threats to Operational Technology are Real and Challenging

Like other industries that provide critical services, such as healthcare or energy and utilities, manufacturing has a low threshold for operational downtime, which can create barriers to implementing a strong security posture for industrial systems. Threat actors know that manufacturing is critical to the global economy, making it an ideal target for disruptive cyberattacks. According to IBM X-Force’s 2025 Threat Intelligence Index, manufacturing is the #1-targeted industry for cyberattacks globally for the fourth consecutive year, accounting for 26% of all documented incidents within critical sectors, even surpassing finance and insurance. Further compounding the issue, traditional security tools may be insufficient to protect connected OT environments.

OT security ensures the availability, integrity, and confidentiality of physical and industrial processes and controls, including industrial control systems (ICS), supervisory control and data acquisition (SCADA) systems, systems that control and monitor equipment, and IoT devices. Whereas IT security primarily focuses on safeguarding sensitive businesses or customer information, OT security protects against cyber risks with the potential to disrupt physical processes that can have immediate and potentially severe consequences on safety and production.

Technological advancements— such as artificial intelligence (AI), machine learning (ML), and increased cloud— continue to shape the OT threat landscape. Throughout the remainder of 2025, several trends have the potential to influence OT security significantly:

1. Legacy Systems and Unpatched Vulnerabilities

Many modern technologies have short lifespans— personal phones and computers are often replaced every few years. OT systems are designed to have longer lifespans, and older systems were not designed with cybersecurity in mind. Many OT workstations still run end-of-life operating systems, such as Windows XP.

The National Institute of Standards & Technology (NIST) Guide to Operational Technology (OT) Security notes that the lifespan of an OT system can exceed 20 years, which makes patching operating systems and other known software vulnerabilities complex. NIST guidance recommends leveraging compensating controls wherever possible. Aligning defenses with the NIST Cybersecurity Framework or another cybersecurity assessment framework, such as ISO/IEC 27001 or CMMC, can also help improve resilience by providing a structured approach to identifying, mitigating, and monitoring security risks across OT and industrial networks.

2. Proliferation of Connected Devices

The number of connected Internet of Things (IoT) devices has sharply increased over the last several years, transforming everything from factory-floor robotics to predictive maintenance systems. As of 2025, there are an estimated 18 billion devices, a figure expected to more than double to 40 billion by 2030. For manufacturers, this growth has brought significant advancements—from automated quality control sensors to real-time supply chain tracking platforms—that enable greater efficiency, automation, and operational insight.

The rapid proliferation of Industrial Internet of Things (IIoT) devices has dramatically expanded the attack surface for operational technology (OT) environments and industrial networks, making them a prime target for malicious actors. Securing these assets is no small task: traditional passive scanners used for asset inventory and vulnerability assessment often cannot handle the complexity and traffic patterns of IIoT and OT networks. This leaves critical blind spots, making it more difficult to detect, assess, and mitigate vulnerabilities in increasingly interconnected manufacturing systems.

3. Convergence of IT and OT Systems

Previously, IT and OT environments were separate and distinct. OT systems were isolated and ran proprietary controls and protocols using specialized hardware and software.

Over time, there has been a convergence, with OT systems increasingly resembling IT systems as they adopt IT technologies to promote corporate connectivity and remote access, exacerbating cybersecurity risks. Threat actors can exploit vulnerabilities in the IT network, pivot into the OT environment, and potentially disrupt critical industrial processes. In worst-case scenarios, this can result in physical damage to equipment or infrastructure, jeopardizing productivity and safety.

While there is a clear need to introduce security controls into OT environments, NIST recommends taking precautions when introducing security solutions to OT environments. In some cases, it may be necessary to tailor security solutions to the OT environment.

4. Ransomware Attacks

Threat actors have increasingly targeted critical infrastructure sectors, using ransomware to extract payment under the threat of significant disruption. Manufacturing and industrial organizations have a low downtime threshold, making them an ideal target for ransomware attacks. This urgency makes them more attractive to cybercriminals, who are well aware of the pressure manufacturers face to minimize downtime and maintain production schedules. Already, there have been several high-profile incidents that highlight the risk ransomware poses to manufacturing operations.

On February 22, 2025, Ganong Bros.—Canada’s oldest family-owned candy manufacturer—was “brought to its knees by a few clicks” after experiencing a ransomware attack that froze systems in the middle of production at their St. Stephen plant, halting operations. While the root cause of the attack wasn’t disclosed, a forensic investigation identified the “PLAY” ransomware collective as the likely attacker. Ultimately, Ganong Bros. restored operations within a week, but the incident underscores how a single breach can disrupt production, strain recovery resources, and expose the inherent vulnerabilities in today’s tightly interconnected manufacturing supply chains.

5. Supply Chain Vulnerabilities

Supply chain attacks have also become a growing concern as threat actors increasingly target trusted vendors and third-party services. By compromising trusted vendors, attackers can gain access to a much wider pool of victims. The impact of a successful supply chain attack can be devastating, potentially affecting numerous OT environments and leading to cascading failures across industries.

Already, there have been several notable supply chain attacks that highlight potential risks to OT environments. While the 2020 SolarWinds cyber attack primarily targeted IT systems, the compromised Orion software was used widely across different industries, including manufacturing and industrials. The 2023 MOVEit breach impacted hundreds of organizations, exposing data and disrupting operations across a range of industries. Finally, in June 2025, food distributor United Natural Foods Inc. suffered a large-scale cyberattack that forced the company to shut down critical systems, halting operations and causing widespread delays in shipments.

These security incidents demonstrate how a single breach in the supply chain can quickly multiply the attack surface, making it difficult for organizations to detect, isolate, and respond to the threat before significant damage is done.

How to Defend Against OT Cyberthreats

OT environments now face the same types of threats that have plagued IT systems for years. As the threat landscape continues to evolve, securing OT systems requires a proactive and multifaceted approach.

To forty OT security, manufacturers should consider the following security strategies:

- Device visibility and monitoring: Step one of any security program is always an inventory of all network-accessible devices. This foundational step provides insight into which OT/IoT devices or systems are discoverable and identifies software or hardware vulnerabilities.

- Targeted network segmentation: Once a threat actor gains access to a network, they typically try to move laterally and gain access to other systems or sensitive information. Segmented networks to prevent the spread of malicious activities and enforce strict access controls.

- Use real-time monitoring and anomaly detection: Continuous visibility and monitoring of OT systems allows organizations to quickly identify and respond to unusual activities, minimizing the risk of potential attacks and operational disruptions.

- Control access to the system: Enforce robust physical security measures and strict access control management to prevent unauthorized access to critical OT infrastructure.

- Develop an incident response plan: Incident response plans serve as the building blocks for recovery after a disruptive cyber incident. Be sure to should create a plan specifically tailored to OT environments.

How Asimily Helps Defend OT Environments

Cyber threats against OT will continue to evolve, especially as OT environments become increasingly connected. There are risk management and reduction steps organizations can take to manage cybersecurity threats to industrial networks.

Asimily is a trusted partner for industrial OT security. Our comprehensive platform is designed to meet the unique needs of OT security, such as continuous flow processes and uncommon device protocols. With Asimily, you get targeted protection and continuous monitoring of your entire environment. Asimily’s inventory and vulnerability detection capabilities are built to monitor traffic to and from OT equipment and proactively identify issues.

In the event of a security incident, our platform, with its rapid response features, quickly captures packets to aid incident responders. With Asimily, teams can keep a handle on their OT attack surface and ensure they are as safe as possible, providing a sense of reassurance.

To learn more about Asimily, download our whitepaper, IoT Device Security in 2024: The High Cost of Doing Nothing, or contact us today.

Secure Every IoT Device.

Automatically.

Cyber threats move fast — so should you. Asimily gives instant inventory and smart, prioritized risk mitigation insights for every IoT, OT, and IoMT device — so you can take action before threats strike.